Analysing tele-connections between raw material extraction and consumption

Various international policy processes, most prominently the UN Sustainable Development Goals (SDGs), require robust indicators for resource efficiency of production and consumption to inform about the success of policies that aim to improve the overall resource efficiency of national economies and thereby reduce environmental pressures and impacts of economic activities. In an increasingly globalised world, comprehensive indicators are required that cover the whole supply chains of primary materials, goods and services spanning across countries and continents. For the category of raw materials, the indicator ‘material footprint’ has been introduced. It comprises material extractions that enter the economy and are directly and indirectly required to satisfy domestic final demand in a specific country, independently of the geographical location of material extraction.

Which parts of the supply chains are responsible for the highest deviations in material footprints?

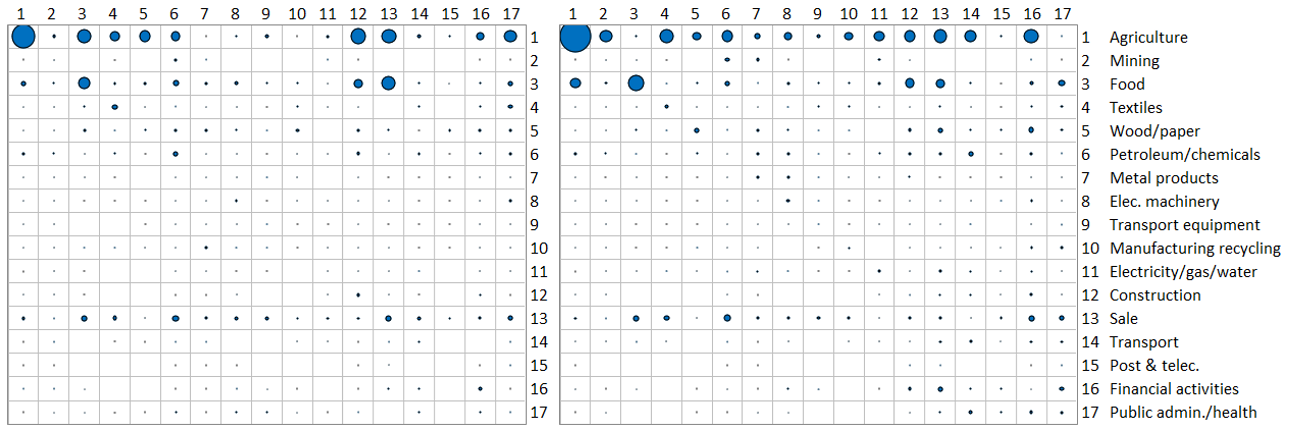

Various economic-environmental databases exist that allow calculating material footprints. However, applying these different databases leads to diverging results. In this paper, we therefore investigate which deviations between the databases exist and which parts of the supply chains are mostly responsible for differences in overall material footprint results. We found that across all analysed countries and material groups, data differences in the primary material extraction sectors (i.e. agriculture, forestry and mining) and in the subsequent processing sectors (such as food, petroleum and chemicals, metal products or construction) were responsible for around 60% of the difference in material footprint indicators. In contrast, data differences in sectors, which receive materials at later stages in the supply chain, such as manufacturing or services, generally have only a minor impact on the demand-based material flow indicator. We conclude that the material-intensive sectors and supply chains should be a priority in the further development of models and databases that calculate material footprint indicators.